Lights-out automation works in some process industries, especially where human contact can potentially damage or contaminate products such as food, microchips and pharmaceuticals. For instance, the creative and cognitive power of humans can easily improvise and solve problems related to assembly tasks.”

There are many things that robots can’t do that humans can. “Many companies failed at attempts to implement lights-out automation in the past, because humans can often do a much better job than machines,” explains de Boer. “Instead, the lean manufacturing movement of the last two decades has showcased the power of the human operator on the factory floor. “The concept of lights-out factories, where there’s only machines such as robots operating, hasn’t been talked about much among discrete manufacturers since the 1980s,” says Enno de Boer, global head of manufacturing at McKinsey & Co. Last year, after throwing in the towel and replacing robots with humans at his controversial factory in Fremont, CA, Elon Musk tweeted that “excessive automation at Tesla was a mistake….Humans are underrated.”

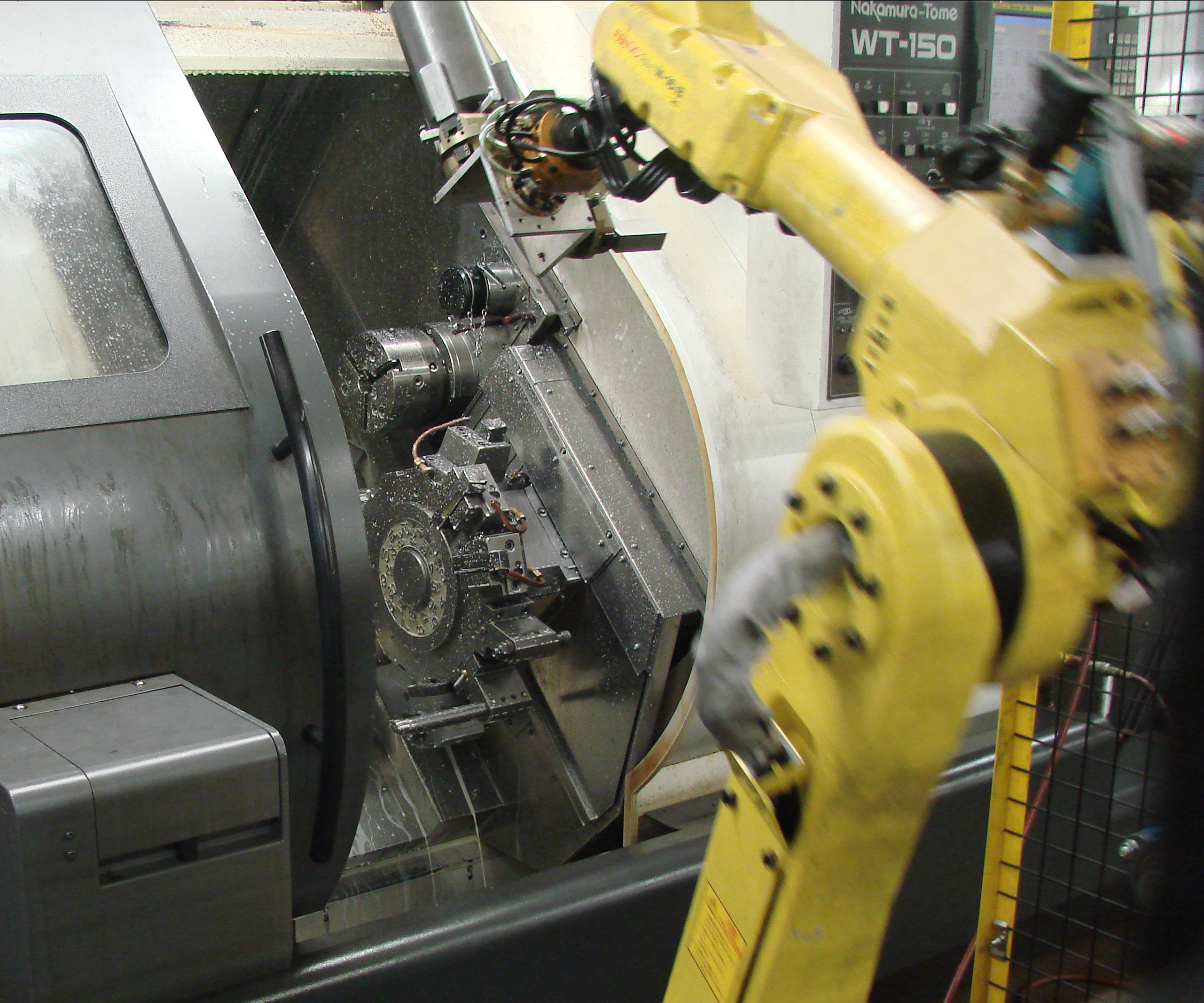

While many manufacturers now use a wide variety of robots, conveyors and other types of automation, people remain the most flexible “machine” available for performing many types of assembly tasks. However, squeezing humans entirely out of the assembly process often proved to be more expensive and more difficult than most people first imagined.Īfter decades of machine advances, recent lean manufacturing initiatives have once again stressed the importance of the human element. That led to a widespread automation scare and a backlash from organized labor. Once upon a time, manufacturers in a wide variety of industries attempted to automate everything and remove the entire human element with lights-out factories. Today, the growing popularity of collaborative robots has eliminated many traditional boundaries. However, human-machine interaction dramatically changed in the 1960s with the advent of computers, numeric controls and robots. Most early assembly lines were designed around machines human interaction was merely an afterthought.īy the time the term “automation” first appeared in the late 1940s, machines were idolized as the backbone of the American economy. For many decades, the universal goal in manufacturing was to create a factory that ran like a machine.

0 kommentar(er)

0 kommentar(er)